Services

Tool & Die Design

Efficiency and effectiveness are evident in our years of experience in tool and die design. From line dies and transfer dies to progressive and hot stamping dies, Thompson Machine the Tool & Die Group, Inc. has refined the craft of design and creation to be one whose primary focus is innovation and quality. We’ll discuss what you’re aiming to achieve, then using the latest software, we’ll design and develop a die that perfectly reflects your vision and adheres to industry standards and regulations. Using highly specialized software and the professional insight of our toolmakers, we’ll work to design parts, dies, and processes that reduce errors and maximize productivity and cost efficiency.

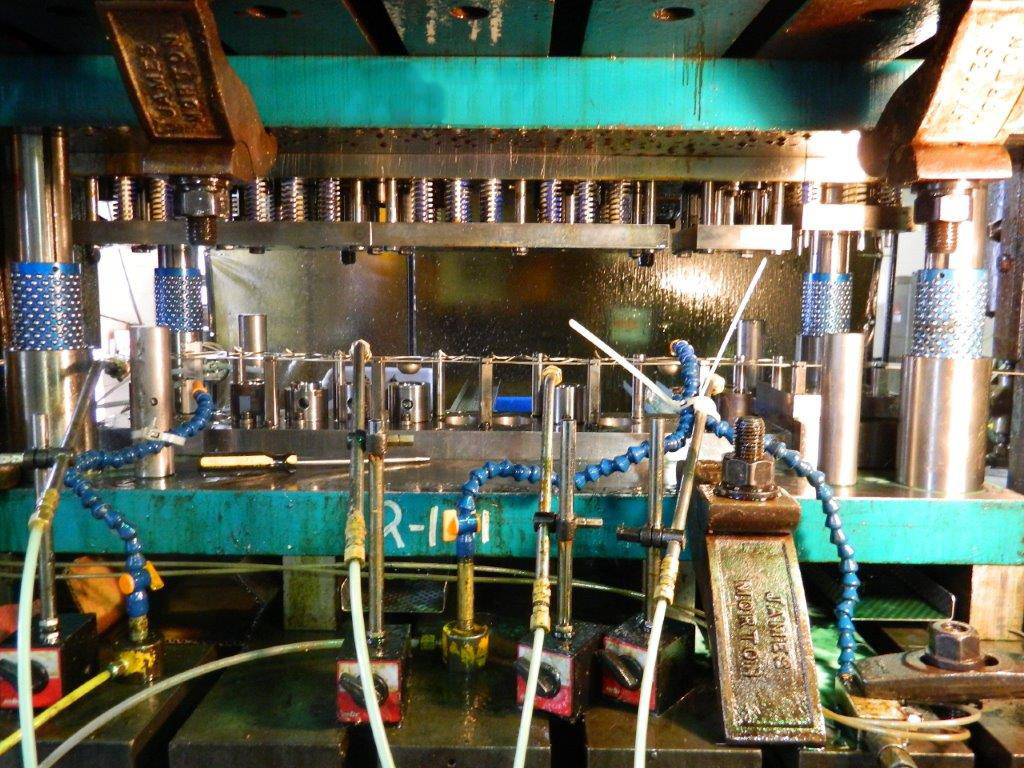

Tool & Die Manufacturing

From engineering and designing to production and construction, Thompson Machine leads the industry in metal stamping dies and tooling system solutions. Quality is at the forefront of all of our productions, and we go the extra mile to ensure that your manufacturing system is completed to the highest standards. First, our experienced technicians assemble, productionize, and validate both the tooling and customer products, then we use the latest inspection technologies and scanner software to ensure that each die is precise, durable, and long-lasting. Combining advanced technology with innovative systems, we work quickly and efficiently to replace components or build entirely new manufacturing systems. For top-quality manufacturing and production, choose Thompson Machine the Tool & Die Group, Inc.!

Prototype & Production Stamping

We understand that innovation in any industry is at an all-time high demand, and we’re here to help you deliver! Our tradesmen combine your vision with their professional insight to create a prototype and production stamping specific to your industry, job, and its requirements. Using the most cost-effective, durable materials, we make your prototype in-house and inspect each to ensure maximum quality. Not only does prototype and production stamping allow for a more efficient and effective manufacturing process, but it also ensures that each part is designed and performs as expected. Our goal is to provide each of our customers with quick development, responsive support, on-time delivery, and most importantly, a high-quality product.

SPC

Our diligent press room staff is well trained in the use of calibrated inspection tools for on-line, computerized SPC data collection. You can be assured of our commitment to excellence in the production of your product.

We attain excellent process capability with online SPC, utilizing computerized input and data analysis. Tracking trends maintains optimal quality control of your products.

Quality Assurance

Backed by years of experience and proven results, Thompson Machine the Tool & Die Group, Inc. guarantees that each job will be completed to the utmost quality, every time! Our intention is to have zero defects and maintain the quality expectations we’ve set through a series of procedures and protocols. All of our tooling, parts, and components go through a rigorous inspection process, in which we assure that they’re designed, produced, and perform as needed. Additionally, we make sure all products and materials go through an analysis to ensure they meet specified requirements. Throughout the production process, we carefully monitor, measure, and record the unique characteristics of each product and material to guarantee that each tool and die meets our high standards of quality.